|

Engineering Simulations Inc. has performed hundreds of finite element analyses that were used to check conformance to ASME Section VIII Division 1 and 2 Code criteria. Our reports are routinely reviewed by Alberta Boiler Safety Association or Technical Standards and Safety Authority in Ontario.

Our analysis methodology follows the rules of ASME VIII Division2, Mandatory Appendix 4: Design Based on Stress Analysis. Stresses are classified as either primary or secondary, depending on the type of load applied. They are then linearized into membrane, bending and peak stresses, along paths chosen through the pressure boundary of each component. ESI has created custom macros that extract the stresses in the coordinate system appropriate for the vessel component and combine them according to Option 3 of Table C-1 in Welding Research Council Bulletin 429: 3D Stress Criteria Guidelines for Application.

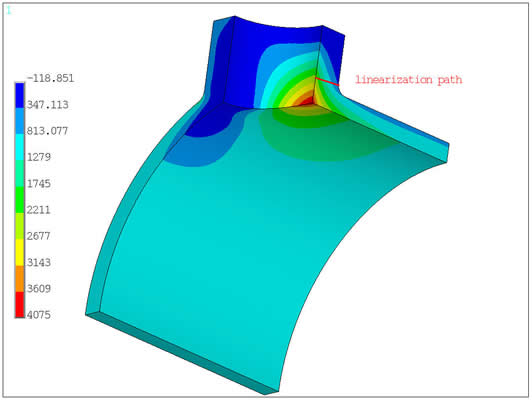

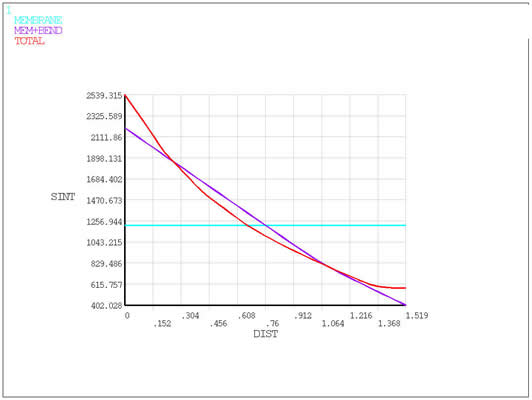

A typical ESI report includes plots of stress (tensile and/or stress intensity) and shows the linearization paths chosen for Code comparison. The variation of membrane, bending and total stress are shown graphically for each path. Tables that clearly summarize the ASME allowable value for the particular load case (including k-factors from AD-150.1) are also supplied.

| Membrane | M+B Inside | M+B Outside | |||

| Predicted | Allowable | Predicted | Allowable | Predicted | Allowable |