|

Engineering Simulations Inc. major area of activity is the prediction and evaluation of stress in a component or assembly of components. Those stresses may be the result of many different types of loads, including applied forces and/or moments, pressure or vacuum, acceleration/vibration, wind, seismic, impact, or differential thermal expansion.

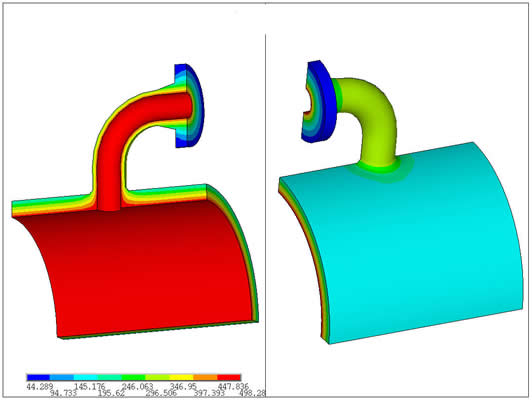

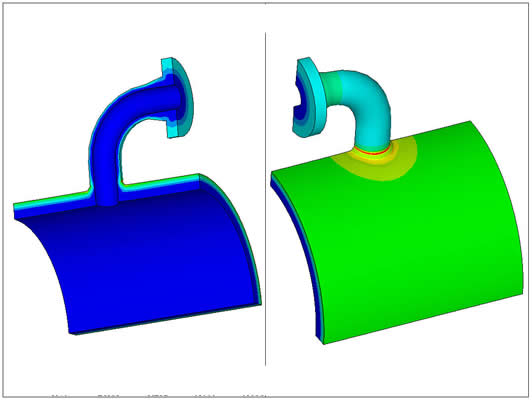

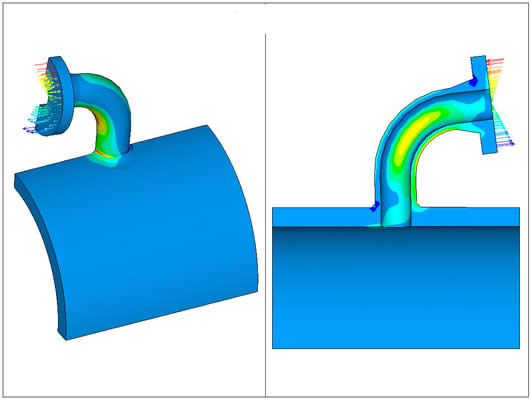

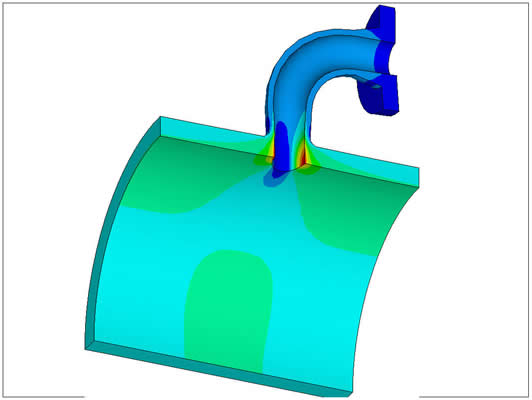

Below, a typical component is analyzed for stress due to differential thermal expansion due to hot internal conditions and ambient external conditions. Figure 1 shows the temperature variation, and Figure 2 shows the concomitant stress field. Figures 3 and 4 show stresses due to a bending moment on the nozzle and internal stress, respectively.

Figure 1: Temperature variation

Figure 2: Thermal stress

Figure 3: Bending stress

Figure 4: Pressure stress